ㅤ

3D Printed Silk Implants and Scaffolds

Additive manufacturing approaches enable new applications for silk-based biomaterials, including patient-specific implants for soft and hard tissue engineering. 3D printing techniques being explored include direct solution extrusion, paste extrusion, digital light processing (DLP) and Freeform Reversible Embedding of Suspended Hydrogels (FRESH) printing.

Silk Micro- and Nano-spheres

Silk fibroin-based micro- and nanospheres with diameters that can be tuned from 300 nm to 20 µm are fabricated using an aqueous preparation involving phase separation between silk and poly(vinyl alcohol) (PVA). Water insoluble, biocompatible, and biodegradable silk spheres hold potential as drug carriers with tunable release profiles for a variety of biomedical applications.

Silk Polyelectrolytes for Live Cell Nanocoating

Ionomeric silk polyelectrolytes are synthesized by carboxylation and amination of the silk protein backbone through chemical modifications. Silk ionomers with a net positive or negative charge are deposited on charged surfaces, including the plasma membrane of living mammalian cells, through electrostatic layer-by-layer assembly. Cytocompatible silk nanocoatings act as artificial cell walls, bringing the cells to a bionic state and providing cytoprotection against mechanical forces. Surface engineering of animal cells through silk nanocoatings offers potential benefits in cell therapies, 3D printing, and preservation.

Silk Nanofibres

The silk fibers are produced from aqueous solution at ambient temperature and pressure using electro- or wet-spinning methods and can be used as biomedical textiles or fiber-based implants. The high surface area of the fiber mats favors cell adhesion, such as for blood vessel grafts and nerve guides. Fibers can be woven, knitted, or braided for enhanced mechanical properties.

Physically-crosslinked Silk Hydrogels

Physically crosslinked silk hydrogels with tunable mechanical properties are produced using aqueous silk solutions through self-assembly into crystalline β-sheets via vortexing, sonication, lowering pH, increasing ionic strength, or applying direct electric current. Vortexing and sonication provide a useful timeframe for cell encapsulation before complete gelation, offering potential uses for tissue engineering and injectable cell delivery scaffolds.

Silk Tubes

Dipping, electro-spinning and gel-spinning methods allow for fabrication of silk tubular vessels using aqueous silk solution with control over inner and outer diameters, alignment, and porosity. The tubular silk scaffolds offer numerous tissue engineering applications including blood vessel grafts and nerve guides.

Silk hydrogel microfluidic systems

3D microchannel networks at 100 μm minimum feature resolution with optical transparency, tunable mechanical properties and in vitro and in vivo degradability, and long-term stability in various environmental conditions are produced from enzymatically crosslinked silk hydrogels. The all aqueous-based fabrication process at ambient conditions enables the incorporation of active biological substances such as enzymes and cells in the bulk phase during device fabrication, offering new opportunities in engineering active diagnostic devices, tissues and organs that could be integrated in vivo, and for on-chip cell sensing systems.

Thermally-processed Silk Implants

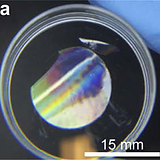

Machinable bulk parts and devices with biocompatibility, biodegradability, and tunable mechanical properties are fabricated by direct solid-state molding of regenerated silk. Under elevated temperature and pressure, amorphous silk chains undergo rearrangement and self-assembly into hard and dense implant materials, allowing processing into a wide range of material formats and composite materials that can also be doped with bioactive components.

Stimulus Responsive Silk Elastin-like Protein Materials

Silk-elastin-like proteins (SELPs) are a family of genetically engineered recombinant protein polymers that combine semi-crystalline silk-blocks and elastomeric elastin-blocks. Depending on the primary amino acid sequence of elastin blocks, SELP materials display reversible material responses triggered by temperature, pH, ionic strength, redox, enzymatic stimuli, or electric fields, thereby becoming candidates for controlled therapeutics release and tissue regeneration.

Silk Films

Nonpatterned or patterned silk films fabricated by casting aqueous silk solutions provide a way to screen materials for in vitro or in vivo testing, pattern cells, embed molecules of interest and test degradation and release. In addition to control over film thickness, porosity can also be induced by mixing poly(ethylene oxide) (PEO) followed by removal with water immersion after water annealing of the films.

Silk Sponges and Injectable Foams

Lyophilized silk sponges and foams with high porosity and structural stability are fabricated using aqueous or hexafluoro isopropanol (HFIP) solutions, providing control over pore size, mechanical and degradation properties. Using injections, foams can also be delivered in vivo. Silk sponges support cell adhesion, infiltration, and growth both in vitro and in vivo, as a biocompatible protein scaffold platform for engineering and regeneration of soft tissues such as, skin, adipose, and neural.